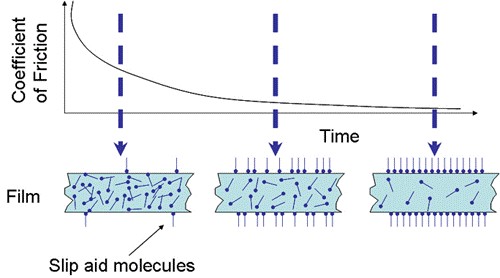

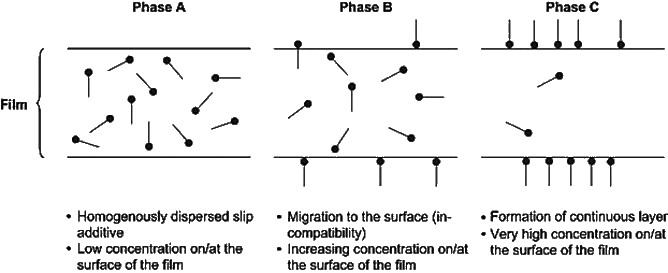

The low molecular material easily migrates to the outer surface of the product immediately after machining and form a favourable gliding layer on the surface, but high concentration may affect the printing on the product. The product uses slip additive that makes surface slides smoothly at time of contact. For the packaging industry, often uses waxes, such as ecuramide, ethylene Bis(streamside), Silicones in Polyethylene and Polypropylene resin.

* Note: Get TDS/MSDS on request