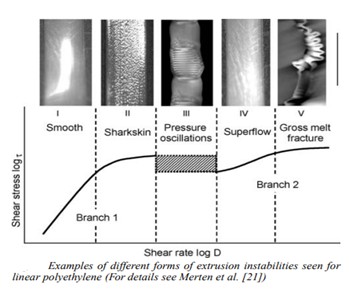

The Defects such as Sharkskin, Pressure Oscillations, Superflow, Melt Facture can be used by using PPA in very little LDR to get highly finished films.

When polymer melts exiting the die, these velocities must even out. When the flow resistance of the material either with barrel wall or die is high and the gap between the shear stresses and the melt velocity reaches a critical value, the polymer chains are disentangled, stretched and cannot cope with the velocity gap makes it “tear”. This phenomenon, also called melt flow instability or disturbance, creates visual defects on the film surface, PPA facilitates to overcome such issues.

The high use of PFAS makes major concern to environment and health of people using it. Some Big players agreed to provide this industry key additives alternate to give latest portfolios of polymer processing aids (PPA) that are free of per- and polyfluoroalkyl substances PFAS. Environmental concerns about PFAS are rapidly growing because studies have shown many PFAS break down very slowly and contaminate the water bodies that are directly impact the humans and seriously deteriorate the biodiversity with water and soil. After studies reports, some countries are restricting PFAS, and there is growing internal and international pressure to ban all PFAS. This is causing processors to search for non-PFAS alternatives

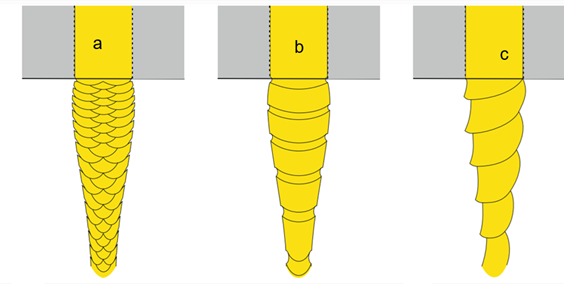

The above pics shows (a) sharkskin, (b) stick-slip (“bambooing”), and (c) gross melt fracture (“corkscrewing”). According to the company these New PPAs eliminate melt fracture or sharkskin effect and reduce die buildup. Their use has been shown to promising result in optimum aesthetic film performance — in terms of clarity, transmittance and haze reduction, with no negative impact on film mechanical and sealing properties. Low or no migration, along with high thermal stability, are also claimed.

Benefits to users, low letdown ratios (LDR) required are said to ensure its competitive cost-in-use. In addition to provide more sustainable alternative with highest possible film performance and quality.

* Note: Get TDS/MSDS on request